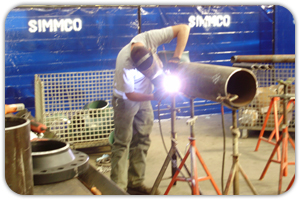

SIMMCO realizes that in today’s industries, you have to be competitive while producing top quality work and unprecedented customer service. Therefore, the only logical choice was to expand our fabrication into a division of it’s own. Initially, our pipe fabrication division was geared toward the furtherance of our construction and mechanical division only. In mid 1995 SIMMCO began installing state of the art equipment to appeal to large industries in process piping, Specialty welding, and related fields. SIMMCO's fabrication facilities total over 400,000 square feet of fabrication space and the equipment to handle any size pipe spools that our customers require. We also have sixty five acres of land for material inventory and/ or room to expand our services. Currently, we produce 1200 large spool pieces within a month. We pride ourselves on being able to offer the industry welds being made at rate of one (1) diameter inch per minute.

Our engineering division can produce shop spool drawings from our customer’s orthographic or isometric drawings or they may be supplied by our clients.

Quality control begins with our shop personnel with visual inspection and progresses through supervision, authorized inspector, hydrostatic test and x ray. Any special testing required can be obtained through independent third party groups. Separation of common and exotic metals is controlled by isolation and separate bay area techniques. Pacification of stainless welds is available if required.

We have an excellent working relationship with our suppliers and timely delivery has never been a problem. We also welcome customer-supplied pipe and fittings, as this is a common practice.